ISO 9001:2015 (TÜV)

Manufacturing expertise and all-round control for impressive quality

We use our technological and manufacturing expertise on a daily basis to produce impressive metal and plastic products – from small to medium-sized batch sizes through to large series. Get to know our technical capabilities and our extensive quality measures here with an initial insight. And let us surprise you with what else we can do for you.

CNC short turning

In CNC short turning, we manufacture workpieces with complex geometries from all machinable materials up to titanium. We machine for you with the following parameters:

| Bar diameter: | 2 - 102 mm |

| Turning length: | 1 - 750 mm |

| Diameter in the chuck: | 5 - 300 mm |

| Minimum batch each: | 500 pieces |

CNC sliding headstock turning

We use CNC sliding headstock turning for the production of parts such as axles, shafts, spindles and particularly slim parts. Cross machining and simultaneous back machining are possible. We machine for you with the following parameters:

| Turning diameter: | 1 - 20 mm |

| Turning length: | 1 - 1000 mm |

| Minimum batch: | 500 pieces |

Complete machining

For us, CNC complete machining means maximum efficiency in the process with the best dimensional accuracy. With the latest equipment, automatic loading technology, 8-axis machining - and with employees who know this supreme discipline of metalworking inside out. This allows us to offer an impressive range of production options. Cross and back machining, polygon production and eccentric turning are all possible in a single operation.

We machine for you with the following parameters:

| Bar diameter: | 2 - 102 mm |

| Turning length: | 1 - 1000 mm |

| Chuck diameter: | 5 - 300 mm |

| Minimum batch in each case: | 1000 pieces |

CNC machining centers

Depending on requirements, we have 4- or 5-axis machines available for milling. Whether turned parts or purely cubic parts, whether blanks, profiles or formed parts - we also machine complex workpieces quickly and efficiently. We machine for you with the following parameters:

| Machining area (L x W x H): | 850 x 700 x 500 mm |

| Minimum batch size: | 500 pieces |

Finishing

We offer the complete range of further processing of your workpiece in high-end quality: For example, we offer specialties such as thread rolling, deep drilling, grinding, milling, roller burnishing ... In-house or with competent partners.

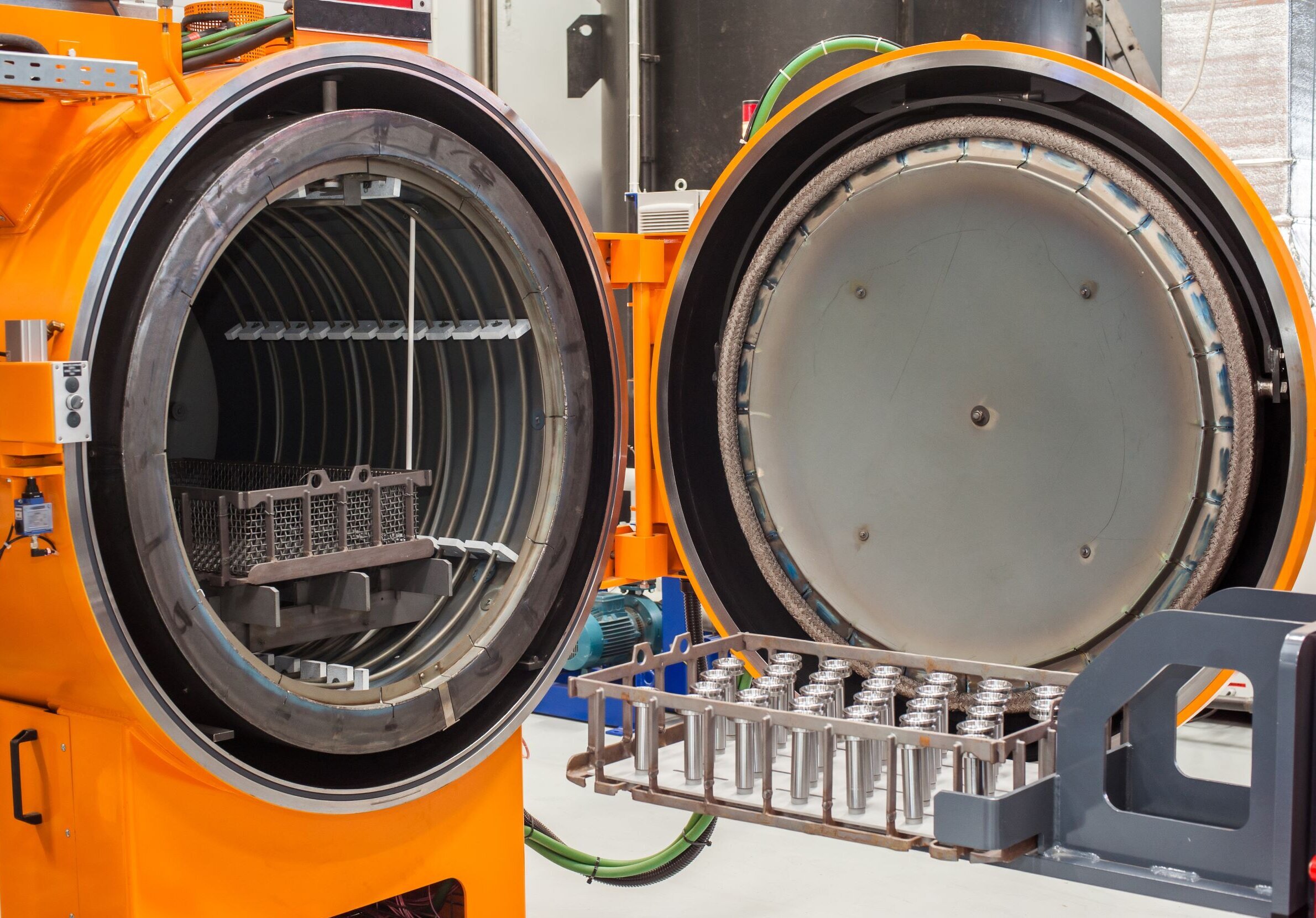

Hardening

Our qualified suppliers master the entire spectrum of heat treatment and are located very close to us. This means that we are also quickly on site to discuss quality issues and support processes.

Types of treatment:

- Tempering

- Case hardening

- Annealing (in inert gas / under vacuum)

- Hardening and tempering (in inert gas / under vacuum)

- Tempering

- Nitriding

- Carbo-nitriding

- Induction hardening

Steel is hardened in order to change its mechanical properties. Hardening is a targeted transformation of the normal material structure. This transformation usually takes place through heating and rapid cooling. The processes used for this are almost as varied as the types of steel that are treated. With a selected network of certified partners, we can realize a wide range of such heat treatments.

Surface treatment

For the surface treatment of machined workpieces, we rely on long-standing, reliable partners in the region. We can offer you virtually every conceivable solution in this area, for example galvanizing, nickel plating, copper plating, chromating, phosphating with manganese or zinc, chemical nickel plating, burnishing, Dacromet zinc flake coating, molycotizing, Teflon coating, micro-encapsulation, TEM deburring, anodizing, alodination, hard coating.

In order to increase the corrosion resistance of materials or to change their tribological properties (sliding properties of the surface), the workpieces can be subjected to galvanic treatment. Our certified suppliers offer a wide range of options for this.

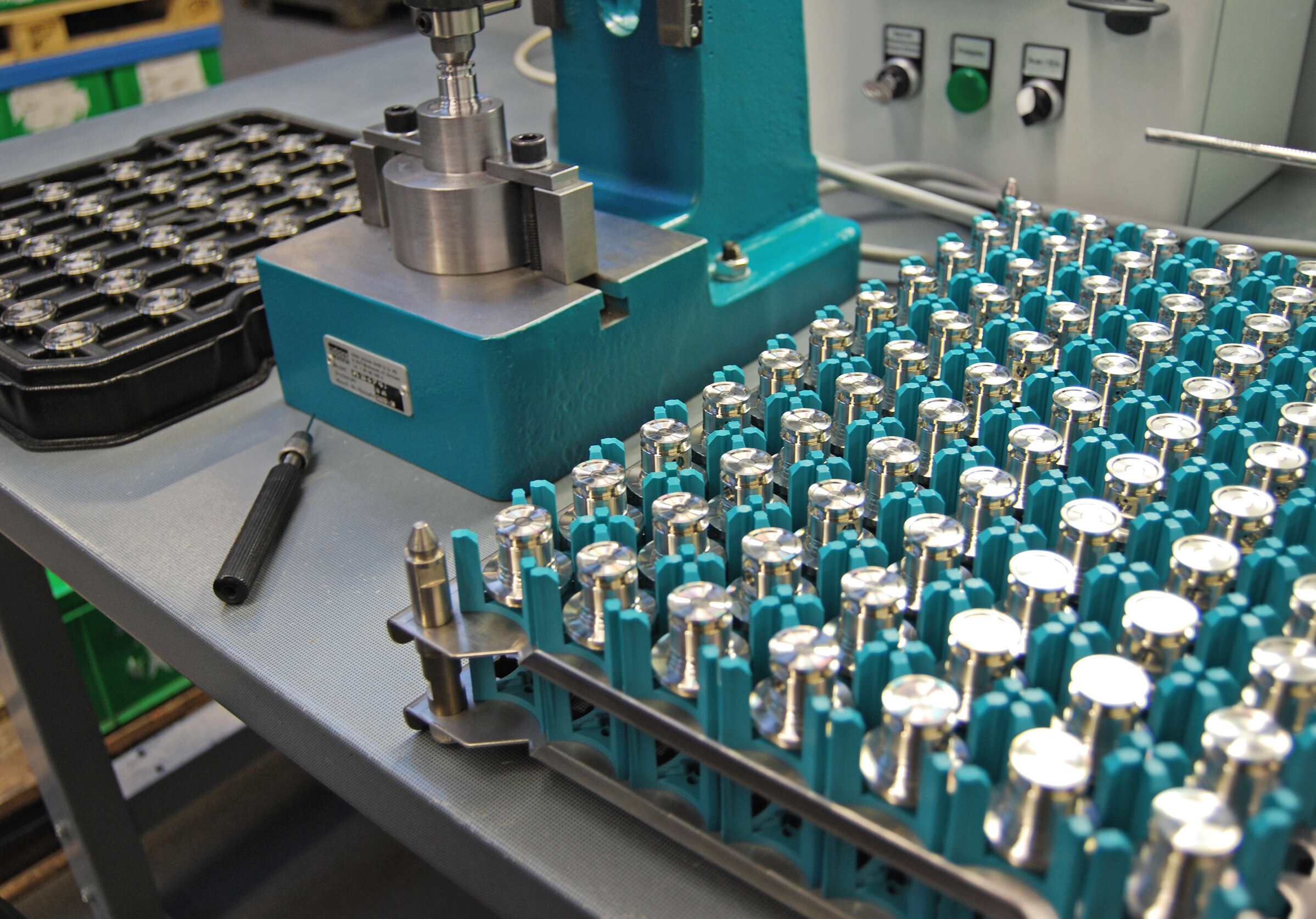

Assemblies

We are also happy to take on the complete production and assembly of modules on request: We embraced the trend towards pre-assembled modules at an early stage, and our assembly expertise is correspondingly versatile and complex today.

Discuss your assembly requirements and associated services with us.

Quality from A - Z

Quality is not an isolated characteristic, but a holistic view of everything that has to do with successful production and the associated process behind it. That's why we at Rees pay attention to countless details, from raw materials to delivery, in purchasing as well as in production and in the measuring room.

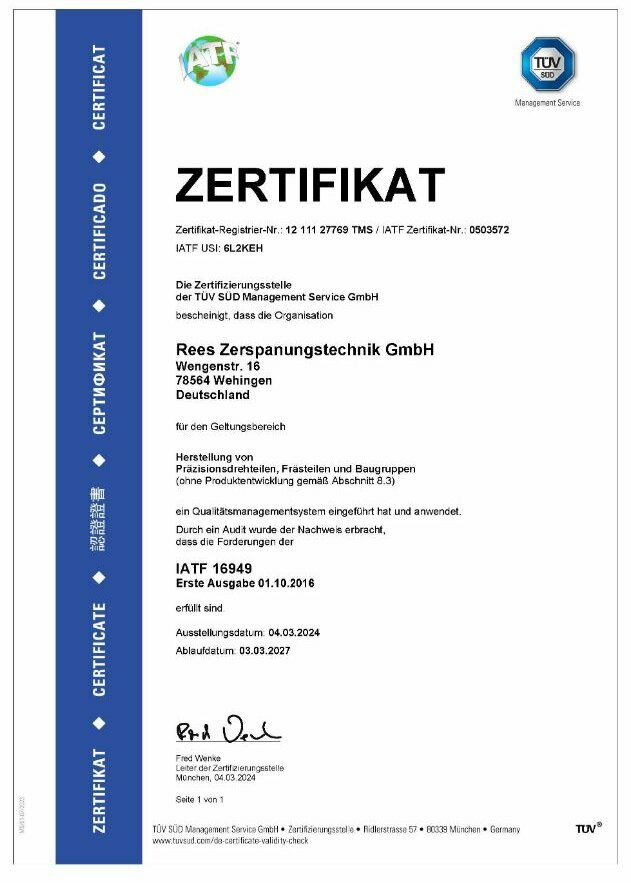

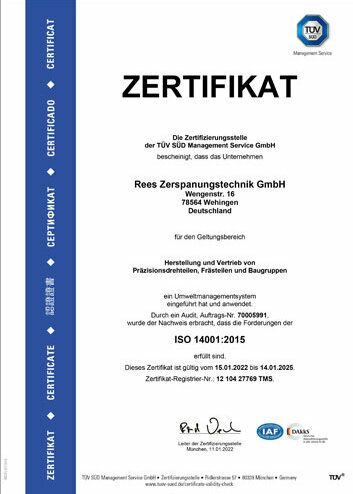

The fact that we know what we are doing is confirmed by our comprehensive certifications and processes documented in accordance with standards. However, we are not satisfied with standards: We scrutinize valid standards and exceed them when necessary.

Our material certificates are original certificates, as this is the only way we can be absolutely sure of the quality of our raw materials. We pay attention to batch purity with our suppliers and support them in project management. Our experienced and trained employees in production ensure the continuous improvement of our processes in quality circles.

How we guarantee optimum quality

Certification and information

ISO 9001:2015 (TÜV)

ISO 9001:2015 (SGS)

IATF 16949

ISO 50001:2018

ISO 14001

EN 9100